QWD Series Mesh Belt Uhlobo Shot Ukuqhushumba Machine

1.Inkcazo ebanzi:

Uluhlu lwe-QWD lweMesh Belt Shot Blasting Machine luhlobo olutsha lwezixhobo eziphuhliswe ngokuzimeleyo yinkampani yethu.

Ngokumalunga nokuhlelwa kwezixhobo zokucoca, kufuneka ibe yi-Q69 Series Ngokusebenzisa uhlobo lwe-Shot Blasting Machine.

Ikakhulu isetyenziselwa umatshini wokuqhushumba owenziwe ngodonga olucekethekileyo;isinyithi okanye i-aluminium i-alloy castings enesici se-thin-walled and fragile;ii-ceramics kunye nezinye iindawo ezincinci, kunye nokomeleza i-workpieces.

Uneempawu zokuqhubeka kakuhle, ukucoca okuphezulu, ukuguqulwa okuncinci, akukho mfuneko yesiseko somatshini, njl njl. unokusetyenziswa yedwa okanye ngokudibanisa nomgca wokuvelisa.

1.Inkcazo ebanzi:

Uluhlu lwe-QWD lweMesh Belt Shot Blasting Machine luhlobo olutsha lwezixhobo eziphuhliswe ngokuzimeleyo yinkampani yethu.

Ngokumalunga nokuhlelwa kwezixhobo zokucoca, kufuneka ibe yi-Q69 Series Ngokusebenzisa uhlobo lwe-Shot Blasting Machine.

Ikakhulu isetyenziselwa umatshini wokuqhushumba owenziwe ngodonga olucekethekileyo;isinyithi okanye i-aluminium i-alloy castings enesici se-thin-walled and fragile;ii-ceramics kunye nezinye iindawo ezincinci, kunye nokomeleza i-workpieces.

Uneempawu zokuqhubeka kakuhle, ukucoca okuphezulu, ukuguqulwa okuncinci, akukho mfuneko yesiseko somatshini, njl njl. unokusetyenziswa yedwa okanye ngokudibanisa nomgca wokuvelisa.

2.Iiparamitha ezingundoqo zobugcisa (QWD800):

| Hayi. | Into | Igama | Ipharamitha | Iyunithi |

| 1 | Igumbi lokucoca | Ubungakanani bokuvula | W900*H480 | mm |

| 2 | Ibhanti yomnatha | Ububanzi bebhanti yomnatha | 800 | mm |

| 3 | Ukusebenza kakuhle kwemveliso | Ulawulo lokuphindaphinda | 0.5-1.8 | m/umz |

| 4 | Intloko ye-Impeller | Umzekelo | QBH037 | |

| Ubungakanani | 8 | iiseti | ||

| I-impeller diametr | 360 | mm | ||

| Isantya sokuhamba kwe-abrasive | 8*180 | kg/min | ||

| Isantya sokuqhushumba | 76 | Nksk | ||

| Amandla | 8*11 | KW | ||

| 5 | Ukudubula kwentsimbi | Ukongezwa kokuqala | 3 | T |

| 6 | I-levator yebhakethi | Ukuphakamisa amandla | 90 | T/H |

| Amandla | 7.5 | KW | ||

| 7 | Umhambisi we-Horizontal Screw | Ukuhambisa umthamo | 90 | T/H |

| Amandla | 7.5 | KW | ||

| 8 | Umhambisi weScrew othe nkqo | Umthamo wokugubungela | 90 | T/H |

| Amandla | 7.5 | KW | ||

| 9 | Umahluli | Ithamo leqhekeza | 90 | T/H |

| Isantya somoya kwindawo yokwahlula | 4-5 | Nksk | ||

| Isiqulatho senkunkuma emva kokuhlukana | ≦0.05% | |||

| Amandla | 4 | KW | ||

| 10 | Inkqubo yebhanti yeMesh | Amandla | 3 | KW |

| 11 | Ingxolo yezixhobo | ≤93 | db | |

| 12 | Amandla onke | 114 | KW |

3.Ukwakheka kweMveliso:

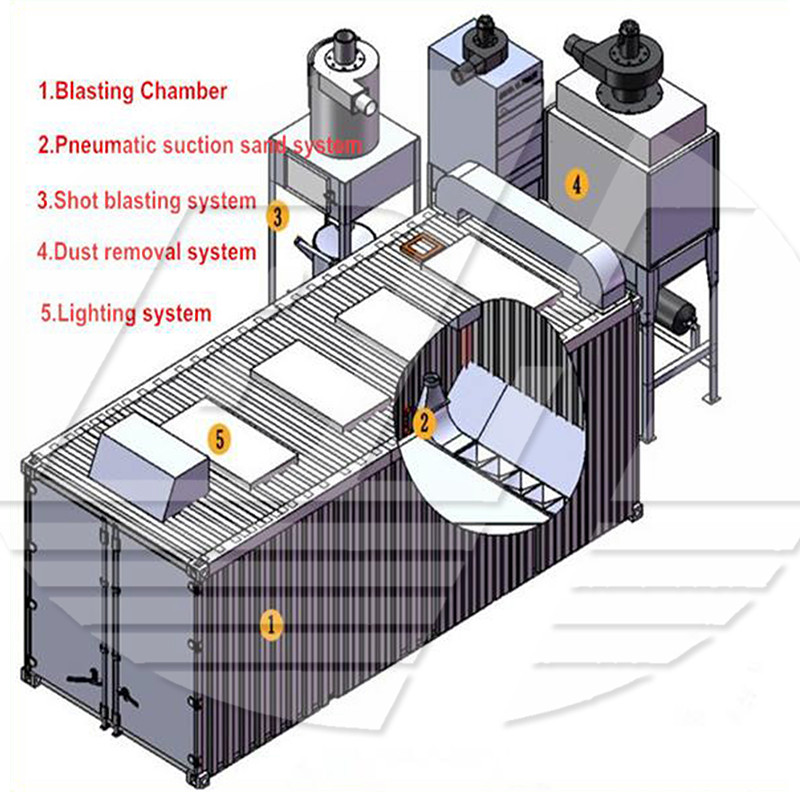

QWD Series Mesh Belt uhlobo Shot Ukuqhunyiswa Machine iqulunqwe igumbi Coca;Igumbi lokutywina;Inkqubo yokuhanjiswa kwebhanti yeMesh;IsiKhowuli se-Longitudinal Screw Conveyor;IsiKhowuli esithe tye;I-Elevator yeBhakethi;Umahluli;iqonga;I-Impeller Head Assembly;inkqubo yokulawula ukudubula kwentsimbi;Inkqubo yolawulo lombane;njl.,

4.Iimpawu eziphambili:

Igumbi lokucoca i-A.Shot Blasting:

Igumbi lokucoca eliqhumayo liqulethwe ngeendonga zecala, iingcango zokufikelela, iindonga eziphezulu, ipleyiti yokukhusela i-Mn13.

Iqokobhe legumbi lokuqhushumba liplati yentsimbi edityanisiweyo, eyindawo evaliweyo kunye nephangaleleyo yokuqhushumba.

Iiseti ezi-8 ze-QBH037 zodidi lwe-Impeller Head assembly zifakwe eludongeni olungaphandle lwegumbi lokudubula.

I-Rolled Mn13 ipleyiti yokukhusela kwigumbi lokucoca igxininiswe ngokuqinileyo ngamantongomane e-hexagon ukuze kube lula ukuchithwa kunye nokutshintshwa.

I-Rolled Mn13 ipleyiti yokukhusela inokuqina okulungileyo kunye neempawu ezicacileyo zokuqina komsebenzi ongaphezulu.(Ngaphantsi kwesenzo somthwalo onamandla wempembelelo okanye umthwalo ogqithisiweyo, umgangatho ogxininisiweyo unzima, kwaye ubunzima bomhlaba bunokuphuculwa kakhulu ukusuka kwinqanaba lokuqala le-HB170 ukuya phezulu kwinqanaba le-HB550, ngelixa i-core igcina ukuqina kwempembelelo elungileyo).

Umsebenzi owenziweyo uthuthwa ngegumbi lokudubula ngebhanti yemesh.

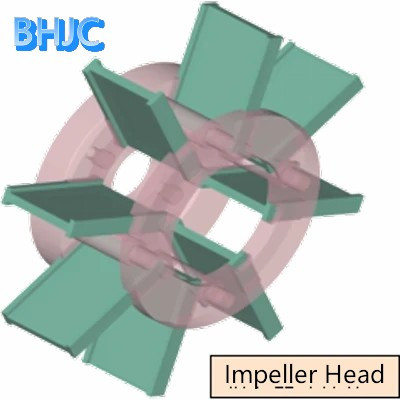

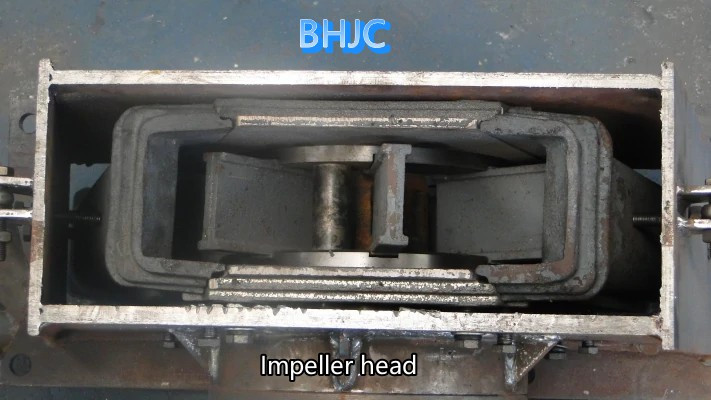

B.Impeller Head Assembly:

Indibano shot blaster iqulunqwe blaster shot, motor, pulley, ibhanti, ibhanti cover, etc. Ukudluliselwa kwamkela B series V-ibhanti.

Olu hlobo lweNtloko ye-Impeller (QBH037) lusekelwe kwiShinto efakwe ngokupheleleyo.Itekhnoloji yaseJapan, kwaye emva kokuphuculwa ngokuqhubekayo, iyilwe ngokuzimeleyo kwaye yenziwa sithi.

Inoncedo olulandelayo:

(1) Ukusebenza okuphezulu: kunye nesakhiwo esikhethekileyo sevili lokudubula, ukudutyulwa kokudubula okusebenzayo kunokufikelela kwi-17.7kg / min · kW.

(2)Ufakelo olukhawulezayo kunye nokuqhaqha iiblades.

(3) Imingxuma ye-shaft esisigxina kunye nomkhono wesalathiso kwikhava zilungiswa ngexesha elinye:

a.Oku kunokwenza umsantsa phakathi komkhono wesalathiso kunye nokudubula okwahlula iyunifomu yevili kunye nokuhambelana.

b.Ayinciphisi kuphela ukunxiba kwevili lokwahlula imbumbulu kunye nesenzeko somkhono wesalathiso sokucinezela, kodwa iphucula kakhulu ukusebenza kakuhle kokudubula.

(4) Ubume kunye nokuchaneka konyamezelo lwemiqolo esibhozo esisigxina kunye nemingxuma kumzimba we-impeller weNtloko ye-Impeller ingqongqo kakhulu.

a.Inkampani yethu yamkela iziko lomatshini elikhethekileyo elithengwe kumazwe angaphandle, elinokuthi ligqibezele inkqubo yonke ukusuka kwisalathiso ukuya ekugayeni okurhabaxa kude kugaywe kakuhle;kunye nokusuka kwi-indexing ukuya ku-drilling ukuya kwi-chambering ukuya kwi-reaming kunye nezinye iinkqubo kwi-impeller ngexesha elinye lokubamba.

b.Iya kuqinisekisa ukulingana kokusebenza kweNtloko ye-Impeller, kwaye umzuzu wokulinganisela uphakathi kwe-12-15n · mm (umgangatho wesizwe 1 8.6n · mm), onciphisa kakhulu ingxolo yezixhobo.

5IJapan, eyenza umahluko wobunzima beblade elawulwa ngaphakathi kwe-2g.Inciphisa kakhulu ingxolo ngexesha lokusebenza kweNtloko ye-Impeller kwaye yandisa ubomi benkonzo yamacandelo asetyenziswayo.

(6) Ipleyiti yokukhusela ephezulu kunye necala lokukhusela umatshini wokudubula ukudubula konke kwamkela isakhiwo esikhethekileyo, kwaye ubukhulu bendawo bufikelela kwi-70mm, okuphucula kakhulu ukuxhathisa ukunxiba kunye nobomi benkonzo yepleyiti yokukhusela.

(7)Imbonakalo entle, ulwakhiwo oluthambileyo, ukwenziwa lula kunye nokugcinwa, ingxolo ephantsi.

(8)Faka isixhobo somda kwiNtloko ye-Impeller: xa i-Top protective plate ivulwa ukulungiswa, qinisekisa ukuba izixhobo azikwazi ukuqaliswa, ngaloo ndlela ukhusela ukhuseleko lwabasebenzi bokulondoloza.

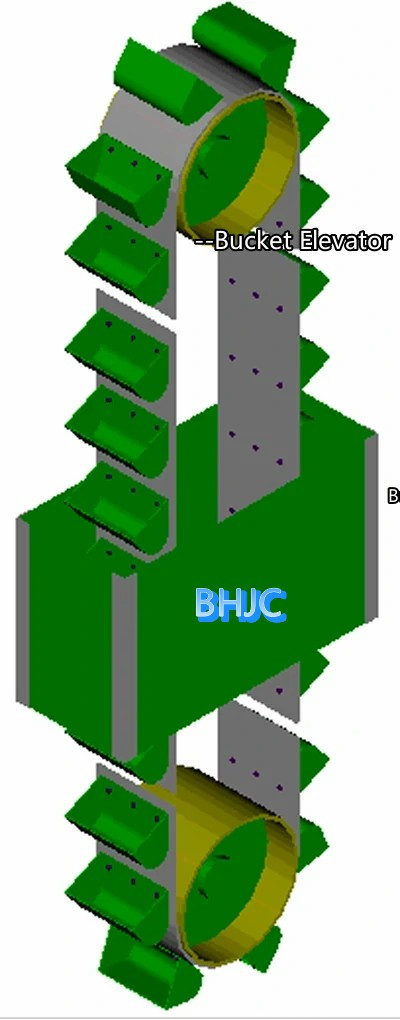

I-C.Bucket Elevator:

I-elevator yebhakethi yenziwe nge-cycloidal pin wheel reducer;Iirola eziphezulu nezisezantsi;ibhanti lokubonisa;ihophaumgqomo ovaliweyo kunye nesixhobo soxinzelelo.

I-port yesondlo esezantsi ye-elevator yebhakethi idityaniswe ne-screw conveyor, kwaye i-port yokukhupha ephezulu idibaniswe ne-mahluli.

Isigqubuthelo se-Bucket Elevator samkela isakhiwo se-welding, kunye nenkangeleko enhle kunye nokuqina okulungileyo.

I-roller ephezulu kunye nesezantsi ithatha isakhiwo se-squirrel cage esine-diameter efanayo, ephucula ukungqubuzana phakathi kwebhanti yokuphakamisa kunye ne-pulley, ukuphepha i-skid phenomenon, kunye nokunciphisa amandla okuqinisa ngaphambili kwebhanti yokuphakamisa.

Ikhava ye-elevator yebhakethi ixhotywe ngomnyango wokufikelela, onokulungisa kunye nokubuyisela indawo ye-hopper.Ngokuvula isivalo somnyango kumnyango osezantsi wokufikelela, i-drive ephantsi ingagcinwa kwaye ibhloko yensimbi yentsimbi ephantsi inokupheliswa.

Lo matshini usebenzisa ibhanti elisicaba ukujikeleza.Ngethuba lokusebenza, i-hopper egxininiswe kwibhanti yokuhambisa iya kukhuhla intsimbi yentsimbi phantsi kwe-elevator;phantsi komqhubi we-elevator motor, i-steel shot iya kukhutshwa yi-centrifugal gravity kwaye ifakwe kwi-Separator.

I-elevator ifakwe iseti yesixhobo soxinzelelo.Xa ibhanti likhululekile, ibhanti kufuneka liqiniswe ngokulungisa iibholiti zokulungelelanisa kumacala omabini angaphezulu kwe-elevator.Uluhlu lohlengahlengiso luyi-100 mm.

Kukho ivili le-pulse kwi-shaft engezantsi ye-elevator yebhakethi, enokubona kwaye ilandelele imeko yokusebenza ye-elevator yebhakethi.Nje ukuba i-elevator yebhakethi ingajikelezi okanye ityibilike, inokubuyisela umqondiso kwi-PLC ngexesha, ukuqinisekisa ukusebenza ngokukhuselekileyo kwezixhobo.

D.Screw Conveyor:

I-screw conveyor yenziwe nge-cycloidal pin wheel reducer, screw shaft, isiciko sokuhambisa, isihlalo, njl.

I-spiral blade yenziwe ngezinto ezi-16Mn, kwaye izangqa zayo zangaphakathi nangaphandle zizotywa emva kokucutshungulwa ngobuchwephesha obukhethekileyo.

I-screw shaft yonke icutshungulwa iyonke emva kwe-welding, ngaloo ndlela iqinisekisa ukubumbana kwazo zombini iziphelo ze-screw shaft.

I-Screw Conveyor ihambisa udubulo lwentsimbi oluqokelelwe yi-hopper esezantsi kwi-elevator ye-emele.

I-pitch kunye nobukhulu besangqa sangaphandle zichaneke kakhulu, nto leyo ephucula ubomi be-spiral kwaye inciphisa ingxolo ehambayo.

Le nxalenye iyinxalenye ebalulekileyo yenkqubo yokujikeleza kwentsimbi yentsimbi yezixhobo.

Kweli candelo, inkampani yethu iye yaqaphela ukulandelelana, kunye nenqaku lokuguquguquka okuphezulu, ukutshintshiselana, okuzinzileyo kunye nokusebenza okuthembekileyo.

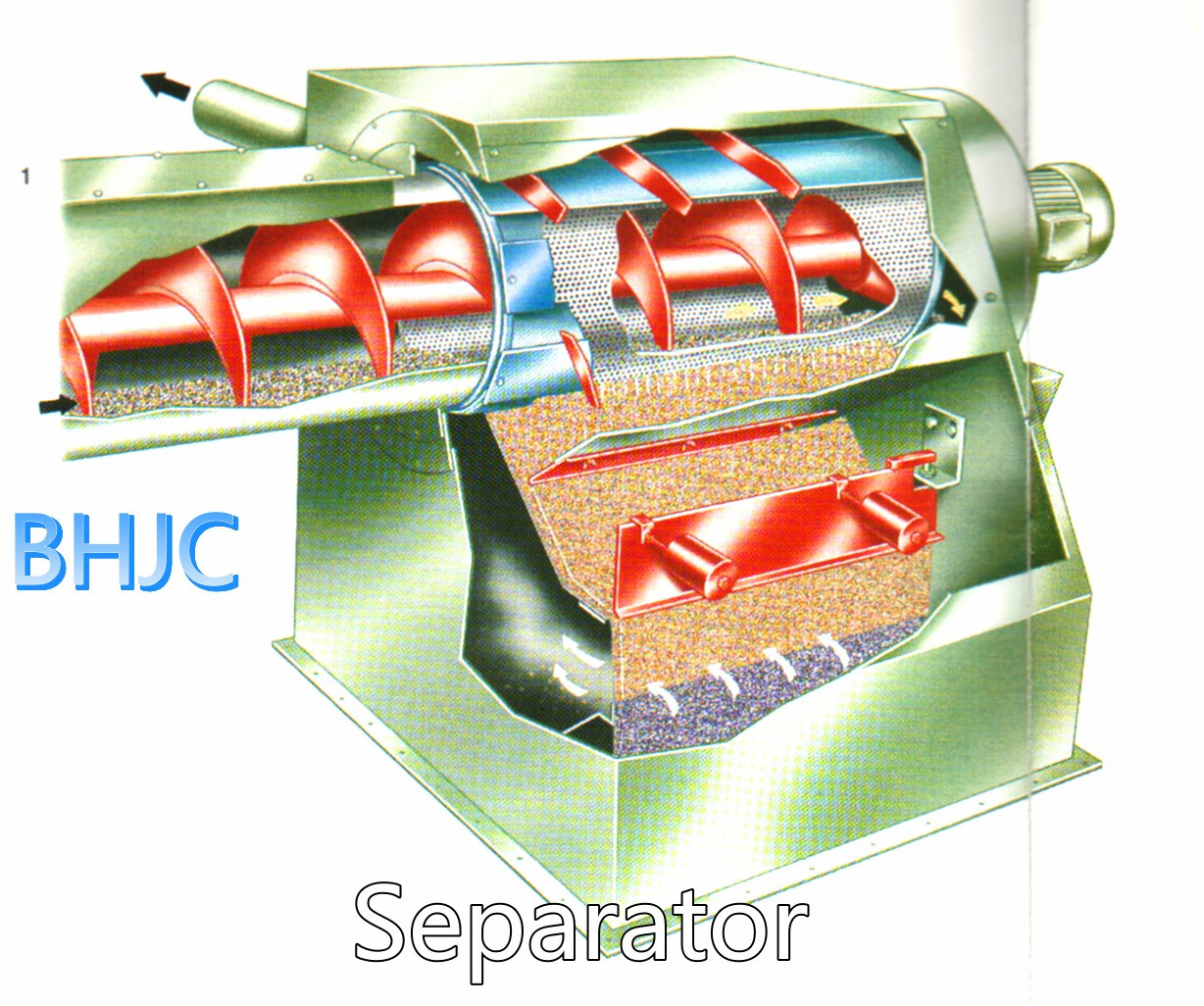

E.umahluli:

Ukwamkela udidi oluphezulu "BE" isahluli esigcwele ikhethini.

Lo mahluko waphuhliswa ngokuzimeleyo yinkampani yethu ngesiseko sokufunxa ngokupheleleyo itekhnoloji ye-Swiss GEORGE FISCHER DISA (GIFA) kunye nenkampani yase-American Pangborn, kwaye emva kokuphucula ngokuqhubekayo.Luhlobo lwamva nje lomahluli wenkampani yethu

Isahluli siqulunqwe ngamacandelo amabini: isikrini segubu kunye nenkqubo yokwahlula umoya.

Ikhusi legubu lenziwe ngamacangci angaphakathi ajiyile, angaphandle ajiyileyo, umzimba wesikrini, i-shaft yenkxaso kunye nenxalenye yothumelo, ucango lolondolozo kunye nesigqubuthelo;

Inkqubo yokwahlula umoya iqulunqwe ipleyiti yokuthintela isanti yomxhuzulane, i-deflector, ipleyiti ye-skimming yenqanaba lokuqala, ipleyiti yenqanaba lesibini le-skimming, i-suction port, i-cover, isikrini, i-anti-wear plate, ibhakethi yokugcina i-shot kunye ne-valve yokulawula umthamo womoya.

Uhlengahlengiso lomahluli:

① Esona siphumo silungileyo sokwahlula soMahluli siphunyezwa ngokulungelelanisa ubume bobunzima kwisango, indawo yokuma kwepleyiti yohlengahlengiso kwipleyiti yokutyibiliza yokuqala neyesibini, kunye nevalve yebhabhathane kumbhobho.

② Ngezi ndlela, umphumo wokwahlukana uya kuba ngaphezulu kwe-99.5%, kwaye uya kunciphisa kakhulu ukuguga kwamagqabi omatshini oqhumayo.

I-diameter engcono kakhulu yokudubula kwensimbi yolu hlobo lwe-Separator yi-0.7 ~ 2.5, kunye nokusebenza kakuhle kokwahlula ≥99.5%.

Inkqubo yokusasaza i-F.Steel shot:

Ivalve yesango lokudubula elawulwa yi-cylinder isetyenziselwa ukulawula ukunikezelwa kwentsimbi yentsimbi kumgama omde.

Singakwazi ngokulungelelanisa iibholithi kwisilawuli sokudubula ukuze sifumane isixa esifunekayo sokudubula.

Le teknoloji iphuhliswe ngokuzimeleyo yinkampani yethu.

Ukukhetha ukudubula: Kucetyiswa ukuba usebenzise ukudubula kwentsimbi, ubulukhuni be-LTCC40 ~ 45.

G.Ulawulo lwenkqubo:

Inkqubo yokulawula umoya:

Inkqubo yokulawula umoya iqulunqwe ngamacandelo okusebenza komthombo womoya, iivalve zomoya kunye ne-actuator pneumatic.Ukuze kuqinisekiswe ukusebenza okuthembekileyo kwezixhobo, iivalvu zomoya zizo zonke iinxalenye zemveliso yasekhaya eyaziwayo.

Inkqubo yolawulo yombane

① Le nkqubo iluqonda lonke ulawulo lomatshini wokuqhushumba.

② Le nkqubo ithatha i-programmable logic controller (PLC) njengondoqo kwaye isebenzisa izixhobo zombane ezikumgangatho ophezulu.Ineenzuzo ezininzi ezifana nokusebenza okuthembekileyo, iqondo eliphezulu lokuzisebenzela, kunye nemisebenzi epheleleyo yokukhusela.

③ Amandla ombane aphambili ale nkqubo amkela i-3 * 380v AC unikezelo lwamandla, i-loop yolawulo ithatha isigaba esinye se-220v AC unikezelo lwamandla, kwaye isiguquli solawulo sinciphisa i-380v yombane ukuya kwi-220v kwaye inikezela kwi-loop yolawulo.

④ Le nkqubo inomsebenzi we-alam osebenza ngokugqibeleleyo ukunceda abaqhubi okanye abasebenzi bolondolozo ngokukhawuleza ukuba bafumane iphoso, ukunciphisa ixesha lokuphumla, kunye nokuphucula ukusebenza kakuhle.

⑤ Amacandelo ombane ale nkqubo afakwe phakathi kwikhabhinethi yombane ukuze asebenze kunye nokugcinwa lula.

Inkqubo yokuhambisa ibhanti yeH.Mesh:

Inkqubo yokuhambisa ibhanti yemesh ibandakanya ibhanti lokutyisa umnatha, imbaleki ejikelezayo, isixhobo soxinzelelo, njl.

Ibhanti ye-mesh iqhutywe ngesixhobo sokuqhuba esilawulwa yi-converter frequency ukuze kuqinisekiswe isantya somsebenzi ukuze kufezekiswe ukulawulwa kwesantya esisezantsi, ukwenzela ukuba i-workpiece ingacocwa ngexesha elinye.

5.Emva kwenkonzo yokuthengisa:

Ixesha lewaranti yemveliso ngunyaka omnye.

Ngexesha lewaranti, zonke iimpazamo kunye neendawo ezonakalisiweyo zolawulo lombane kunye neengxenye zomatshini ngenxa yokusetyenziswa ngokuqhelekileyo ziya kulungiswa kwaye zitshintshwe (ngaphandle kweengxenye zokugqoka).

Ngexesha lewaranti, inkonzo emva kokuthengisa isebenzisa impendulo "ngoko nangoko".

Iofisi yenkonzo yenkampani yethu emva kokuthengisa iya kubonelelwa ngenkonzo yobuchwephesha kwangethuba kwiiyure ezingama-48 emva kokufumana isaziso somsebenzisi.

6.RAQ

Ukuze unikeze ngezona zisombululo zingcono kwiimveliso zakho, nceda usazise iimpendulo zale mibuzo ilandelayo:

1.Ziziphi iimveliso ofuna ukuzinyanga?Kungcono usibonise iimveliso zakho.

2.Ukuba kukho iintlobo ezininzi zeemveliso kufuneka ziphathwe, Yintoni ubungakanani obukhulu bomsebenzi-wemisebenzi?Ubude * ububanzi * ubude?

3.Buthini ubunzima bowona msebenzi mkhulu?

4.Yintoni imveliso esebenzayo oyifunayo?

5.Naziphi ezinye iimfuno ezikhethekileyo koomatshini?