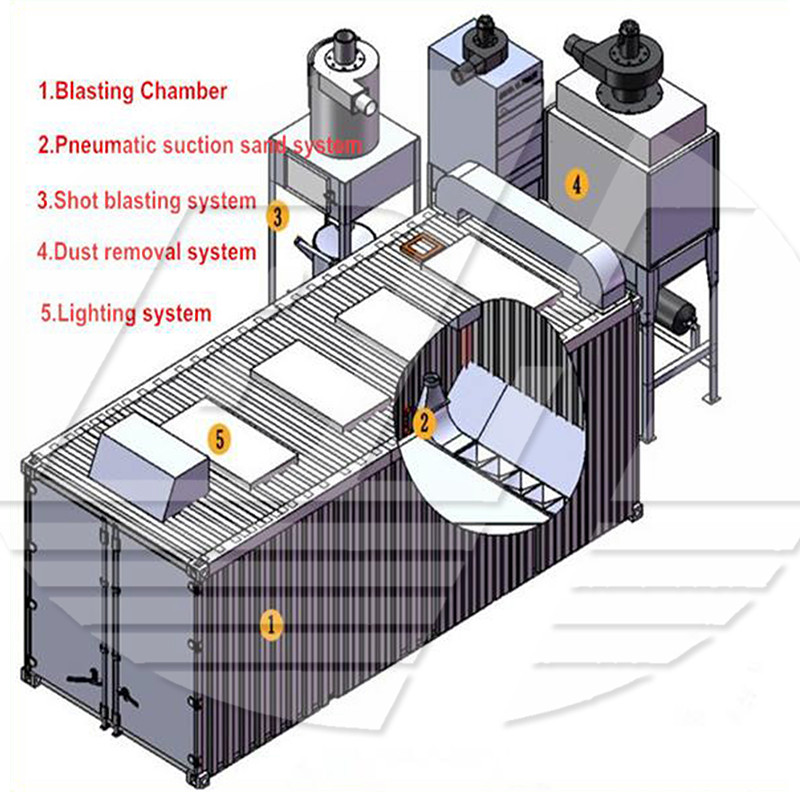

BHQ26 series sandbast cabinet by manual

1.Yintoni ikhabhinethi yokuqhunyiswa kwesanti

Abanye abantu bakwabiza oomatshini bokuqhunyiswa kwesanti, itanki yokuqhunyiswa kwesanti, i-sand blaster ephathekayo, oomatshini bokuqhunyiswa kwesanti kunye nokunye.Amagama ahlukile, kodwa eneneni anentsingiselo efanayo.Inokusebenza ngokwahlukeneyo, kodwa kwiimeko ezininzi isebenza ngegumbi lokuqhushumba.

Ukuqulunqwa kwekhabhathi yokuqhushumba kwesanti ——

Ngokuqhelekileyo, amacandelo alandelayo alandelayo:

1).itanki yokuqhushumba yesanti:

Ubuninzi bentsimbi yentsimbi esetyenziselwa imiqulu eyahlukeneyo yetanki kunye nengcambu yomatshini we-sandblasting iyahluka.Okukhona umthamo mkhulu, kokukhona ityeya ipleyiti yentsimbi.Oku kumiselwa ikakhulu ngumzi-mveliso wenqanawa yoxinzelelo ngokweyona meko.

Kukho iindidi ezimbini zevalve yesanti kunye nevalve yesanti: manual okanye ipneumatic.Ngesandla, kuyimfuneko ukuvula ngesandla i-valve yesanti, kwaye igesi ivulwa ngokuzenzekelayo ngegesi.

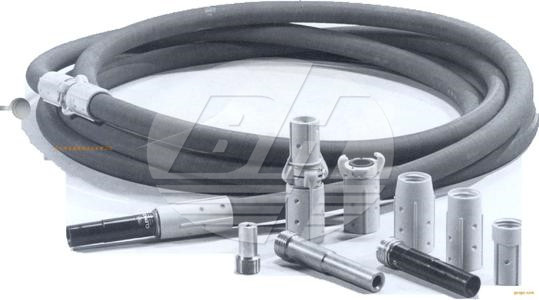

2).Umbhobho wokuqhunyiswa kwesanti (umgangatho yi-10m/20m)

3) .Ivalve yokhuseleko

Uxinzelelo lokusetyenziswa kwetanki yokuqhunyiswa kwesanti ngokuqhelekileyo yi-8KG.Indima yevalve yokhuseleko Xa uxinzelelo lwegesi ludlula i-8KG, luya kuzicima ngokuzenzekelayo.Ukukhusela itanki yokuqhumisa isanti

I-4) .I-Sandblasting gun: Ngokwezinto eziphathekayo, inokwahlulwa ibe yi-boron carbide, i-alloy steel, i-tungsten carbide, isinyithi kunye nokunye.

Eyona nto ihlala ixesha elide i-boron carbide, kwaye ubomi benkonzo ngokuqhelekileyo buyi-500-700 iiyure.

Okwesibini, ubomi benkonzo ye-tungsten carbide kunye nentsimbi ye-alloy ngokuqhelekileyo ziiyure ezingama-300-400,

Intsimbi ingasetyenziselwa iiyure ezili-10 kuphela, bambalwa abantu abayisebenzisileyo.

Inkqubo yolawulo yombane kunye namanye amacandelo.

2.Umgaqo wokuSebenza we-sandblaster ephathekayo

Umgaqo osebenzayo womatshini wokuqhushumba isanti wahlukile kumatshini wokuqhumisa.Umatshini wokudubula usebenzisa amandla aphakathi ukwenza ukudubula.Umatshini wokuqhushumba wesanti uxhotyiswa ngumoya ocinezelekileyo kwaye utshize iibrasives (zombini isanti kunye nesanti engeyiyo isinyithi) phezu kwendawo yokusebenza.Ngenxa yempembelelo yoxinzelelo, i-abrasive kwi-tank yesanti idlula kwi-valve yesanti kunye ne-tube yokuqhuma kwi-spray gun, kwaye i-abrasive ikhutshwe ngesantya esiphezulu, esitshintsha iimpawu zomatshini wendawo yangaphandle yendawo yokusebenza.Ngenxa yempembelelo kunye nefuthe lokusika i-abrasive kwi-workpiece surface , Ukufumana iqondo elithile lokucoceka kunye noburhabaxa obuhlukeneyo kumphezulu we-workpiece, phucula iimpawu zomatshini we-workpiece surface, ngoko ke uphucule ukuxhathisa ukukhathala kwendawo yokusebenza, ukwandisa ukunamathela phakathi kwayo kunye nokwaleka, kwaye wandise ukutyabeka Ukuqina kwefilimu kukwanceda ukulinganisa kunye nokuhonjiswa kwengubo, ukususa ukungcola, ingxolo kunye neengqimba ze-oxide phezu komhlaba, ngelixa i-roughening ubuso be-medium, ibangela uxinzelelo olushiyekileyo kwi-substrate surface kunye nokuphucula ubunzima be-substrate surface.

3.Ingcaciso engundoqo ye-sand blaster ephathekayo

4. Ukulahleka kwamandla kwitanki yokudubula

1).Ulungelelwaniso lomthombo womoya womatshini we-sandblasting ngokubanzi yi-6m³/min (ukusetyenziswa komoya kompu wokutshiza omnye, ukuba yi-N, ubumbeko lomthombo womoya ofunekayo ngu-N*6m³/min.

| Uhlobo lwento | Q0250 | Q0250A-Ⅱ | Q0250A-Ⅱ-LX | ||

| Umthamo wetanki (m3) | 0.5 | 0.7 | 0.82 | ||

| Uxinzelelo lomoya (Mpa) | 0.5-0.6 | 0.5-0.6 | 0.5-0.6 | ||

| Ithamo ekhutshiweyo (umthamo=φ10)(kg/h) | 1800-2280 | 1 umpu | 1800-2280 | 1 umpu | 1800-2280 |

| 2 imipu | 3600-4560 | 2 imipu | 3600-4560 | ||

| Ukusetyenziswa komoya (m3/min) | 6.1 | 1 umpu | 6.0 | 1 umpu | 6.0 |

| 2 imipu | 12.0 | 2 imipu | 12.0 | ||

| Ubude bombhobho oqhushumbayo (mm) | 7000 | 7000 (2pcs) | 7000 (2pcs) | ||

| Indlela yokulawula | Ulawulo LWERIMOTHI | Ulawulo LWERIMOTHI | Ulawulo LWERIMOTHI | ||

| Ubungakanani (mm) | 1036*812*1860 | 1120*900*1890 | 1086*812*2060 | ||

| Ubunzima (kg) | 396 | 500 | 690 | ||

2).Uxinzelelo lomoya olufunwa ngumatshini we-sandblasting ngu-0.5-0.6mpa (ukuba uxinzelelo luphantsi kakhulu, i-sandblasting iya kuba buthathaka kwaye umphumo wokucoca uya kuchaphazeleka).

3).Ubungakanani bokudubula kwesanti / ukudubula ngeyure yomatshini wesanti yi-1800-2100 kg.

4) .Uluhlu lwesicelo sokuqhunyiswa kwesanti

a.Unyango lwangaphambili: zonke iindlela zonyango eziqhumayo ngaphambi kokuba zigqunywe, ezifana ne-electroplating, ipeyinti, ukutshiza, njl., Umphezulu ucoceke ngokupheleleyo, kwaye kwangaxeshanye uphucula kakhulu ukubambelela kunye nokunganyangeki kwe-corrosion layer.

b.Unyango lwangaphambili ngaphambi kokucoca umphezulu weendawo: ukuhla, i-residu kunye nokungcola kweengxenye zetsimbi ezifana ne-castings, i-stamping parts, ii-welding parts, iindawo zokunyanga ukushisa;ukucocwa komphezulu weemveliso ezingezizo zetsimbi, ukususwa kwamabala amnyama phezu kweendawo ezingenanto ze-ceramic kunye nokunciphisa ipeyinti yepeyinti, njl.

c.Ukuhlaziywa kwamacandelo amadala: ukulungiswa kunye nokucocwa kwazo zonke iindawo ezihambayo ezifana neemoto, izithuthuthu, izixhobo ze-electromechanical, njl. Ngelo xesha ukuphelisa uxinzelelo lokukhathala kunye nokwandisa ubomi benkonzo.

d.Ukugqiba ukusetyenzwa kumphezulu we-workpiece: zonke iimveliso zetsimbi kunye neemveliso ezingezizo ezentsimbi (iplastiki, ikristale, iglasi, njl. njl.) imikhondo yomphezulu iyapheliswa, kwaye unyango lomphezulu we-argon wenza ukuba umgangatho wemveliso uphuculwe.

e.unyango lokungunda: Argon ukukhanya inkungu umphezulu unyango umphezulu umngundo, imveliso graphic, kunye nokucoca ngundo, hayi ukonakalisa umphezulu umngundo, ukuqinisekisa ukuchaneka ngundo.

f.Unyango lwe-Burr: Amalungu omatshini asuswa ngee-burrs ezincinci, kwaye iindawo zeplastiki zeendawo zokutofa ziyasuswa.

g.Ukuphinda kusebenze iimveliso ezingathandekiyo: ukususwa kwemveliso engathandekiyo yokugquma, ukususwa kombala ongathandekiyo kumphezulu kunye nokususwa kokushicilela.

h.Ukomeleza: ukwandisa ubulukhuni bomphezulu weendawo zetsimbi kunye nokuphelisa uxinzelelo, njengokunyangwa komphezulu wamaphiko eenqwelomoya, imithombo, izixhobo zomatshini kunye nezixhobo.

i.I-Etching kunye ne-anti-skid processing: iipatheni zokubhala, isicatshulwa kunye ne-anti-skid unyango ebusweni beemveliso zetsimbi kunye neemveliso ezingezona zetsimbi, ezifana ne-marble, i-anti-skid handles, i-seals, i-stele lettering, njl.

j.Unyango lwempahla yedenim: Impahla yedenim imatte, imhlophe kunye ne-whisker yekati iphunyeziwe.

5.Uncedo lwekhabhathi yesandblast:

1).Iinxalenye zetsimbi zomatshini we-sandblasting awonakali, kwaye ukuchaneka kwe-dimensional akuyi kutshintsha;

2).Umphezulu wenxalenye awungcoliswanga, kwaye i-abrasive ayiyi kusabela ngokwekhemikhali kunye nezinto zenxalenye;

3).Umatshini we-sandblasting unokusingatha ngokulula iindawo ezingenakufikeleleka ezifana ne-grooves kunye ne-concaves, kunye nobukhulu obuhlukeneyo be-abrasives bunokukhethwa ukusetyenziswa;

4).Indleko yokucubungula iyancipha kakhulu, ibonakaliswe ngokukodwa ekuphuculeni ukusebenza kakuhle komatshini we-sandblasting, onokuhlangabezana neemfuno ezahlukeneyo zokugqiba umphezulu;

5).Ukusetyenziswa kwamandla aphantsi kunye neendleko eziphantsi;

6).Umatshini we-sandblasting awungcolisi indalo, ukuphelisa iindleko zonyango lwendalo;